RockySea Petro: Leading the Way in API 6D Plug Valve Manufacturing in ChinaA plug valve is a type of rotary valve featuring a closure element, often in the shape of a plunger, which rotates 90 degrees to either connect or separate the channel ports on the valve plug and the valve body.RockySea has attained API Q1, API 6D, and ISO standards, demonstrating its commitment to quality and excellence in plug valve manufacturing. With extensive experience in this field, all products undergo thorough 1

VIEW DETAILSRockySea Petro: A Pioneer in API 6D Butterfly Valve Manufacturing in ChinaA butterfly valve, also known as a flap valve, is a structurally simple regulating valve that can be used for switch control of low-pressure pipeline media. A butterfly valve refers to a valve with a disc as the closing element (valve disc or butterfly plate) that rotates around the valve shaft to achieve opening and closing.RockySea has obtained API Q1, API 6D, and ISO standards. RockySea has rich experience in manufacturing

VIEW DETAILSRockySea Petro: Leading the Way in API 6D Gate Valve Manufacturing in ChinaGate valves are a prevalent type of valve within the API 6D standard, functioning by raising a barrier (gate) out of the fluid path to control flow. When fully open, flat gate valves offer minimal obstruction to fluid flow and find wide application in oil fields and industrial settings.RockySea has attained accreditation to API Q1, API 6D, and ISO standards, demonstrating its commitment to quality. With extensive experie

VIEW DETAILSRockySea Petro: Leading API 6D Ball Valve Manufacturer in ChinaBall valves, renowned for their ability to tightly shut with a mere 90-degree turn and minimal rotational torque, are indispensable for functions like switching and shutting off in pipeline systems. They find extensive utility in cutting off, distributing, and altering the flow direction of various mediums.RockySea Petro boasts accreditation to API Q1, API 6D, and ISO standards, reflecting its commitment to quality. With a

VIEW DETAILSRockySea Petro: Leading the API 6D Check Valve Manufacturing Sector in ChinaA check valve, which operates by the force of fluid flow to open or close, is crucial for preventing medium backflow in pipelines. Belonging to the automatic valve category, check valves are primarily employed in pipelines with unidirectional medium flow to avert potential accidents.RockySea holds certifications in API Q1, API 6D, and ISO standards, demonstrating its expertise in check valve manufacturing. All

VIEW DETAILSRockySea Petro: Leading the API 6D Check Valve Manufacturing Sector in China

A check valve, which operates by the force of fluid flow to open or close, is crucial for preventing medium backflow in pipelines. Belonging to the automatic valve category, check valves are primarily employed in pipelines with unidirectional medium flow to avert potential accidents.

RockySea holds certifications in API Q1, API 6D, and ISO standards, demonstrating its expertise in check valve manufacturing. All products undergo rigorous 100% inspection before delivery to ensure quality.

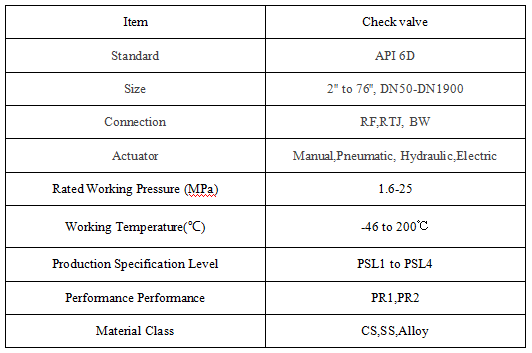

Description

The primary function of this type of check valve is to permit fluid flow exclusively in one direction while obstructing flow in the opposite direction. Typically operating automatically, the valve disc opens under the pressure of fluid flowing in one direction; when fluid flows in the opposite direction, the valve seat is sealed by fluid pressure and the self-weight of the valve disc acting on the valve seat.

Principle

Check valves come in two main types: swing check valves and lift check valves. A swing check valve features a hinge mechanism and a door-like valve disc that rests against an inclined valve seat surface. To ensure proper seating of the valve disc on the valve seat surface each time, a hinge mechanism is incorporated, allowing sufficient swing space for the valve disc to make full contact with the valve seat.

The valve disc can be entirely metal or embedded with leather, rubber, or synthetic covering, depending on performance requirements. When fully open, the fluid pressure through the swing check valve is almost unimpeded, resulting in relatively minimal pressure drop across the valve.

In contrast, the disc of a lift check valve is positioned on the sealing surface of the valve seat on the valve body. Apart from the freely movable valve disc, the rest of the valve resembles a globe valve. Fluid pressure lifts the valve disc from the sealing surface, and when medium reflux occurs, the valve disc falls back onto the valve seat, halting flow. Depending on usage conditions, the valve disc can be all-metal or incorporate a rubber pad or ring. Similar to globe valves, the fluid passage through lift check valves is narrow, resulting in a greater pressure drop compared to swing check valves, with minimal flow rate limitations.

Types

RockySea offers three types of check valves based on structure: lift check valve, swing check valve, and butterfly check valve.

These check valve types are available in four connection forms: threaded connection, flange connection (RTJ, RF), welded connection (BW), and clamp connection.

Data sheet

Contact us

Any question about API 6D Check Valve ( API 6D Check Valve price,API 6D Check Valve for sale) ,please email service@rspetro.com , you will get reply within 12 hours!

RockySea Petro Copyright © 2008-2025 Inc.